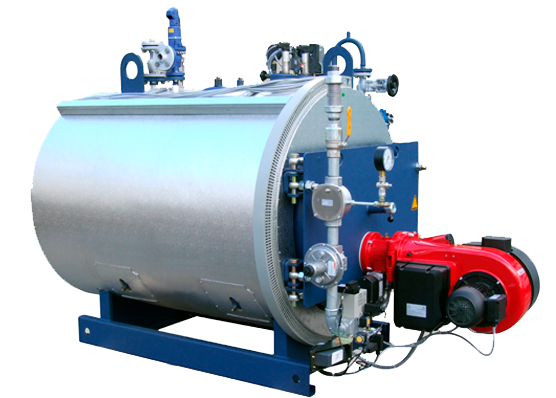

Steam Boilers from Achenbach

Engineering at Achenbach

A highly specialised engineering team of technicians and engineers concentrates on steam boilers and the associated plant technology: Design, supply and installation, optimisation and maintenance from a single source! The steam boiler specialists at Achenbach know almost everything about the efficient use of steam as a heat transfer medium and about saving energy costs by means of heat recovery.